How Cutlery is Made

We wanted to share with you some of the key processes we use to create our stainless steel cutlery…

Following on from our introduction into how William designs cutlery (here), we would like to share the next few steps…

1. Once William has finished refining his development models for a new cutlery range, engineering drawings are issued and sent to our tooling team.

2. The design profile of each utensil is then machined out of solid steel and finished by master tooling craftspeople. They refine the nuances of each edge, curve and contour.

3. Once initial tooling is completed, the master steel molds are used to make a handful of samples to be critiqued. Final metal samples are made, critiqued, and made again until the final sign-off on each cutlery piece is provided.

4. The Master tooling is now completed and must be preserved. Therefore we make identical duplicates of the tooling molds to be hardened (tempered) and made ready for entering the factory for mass-production.

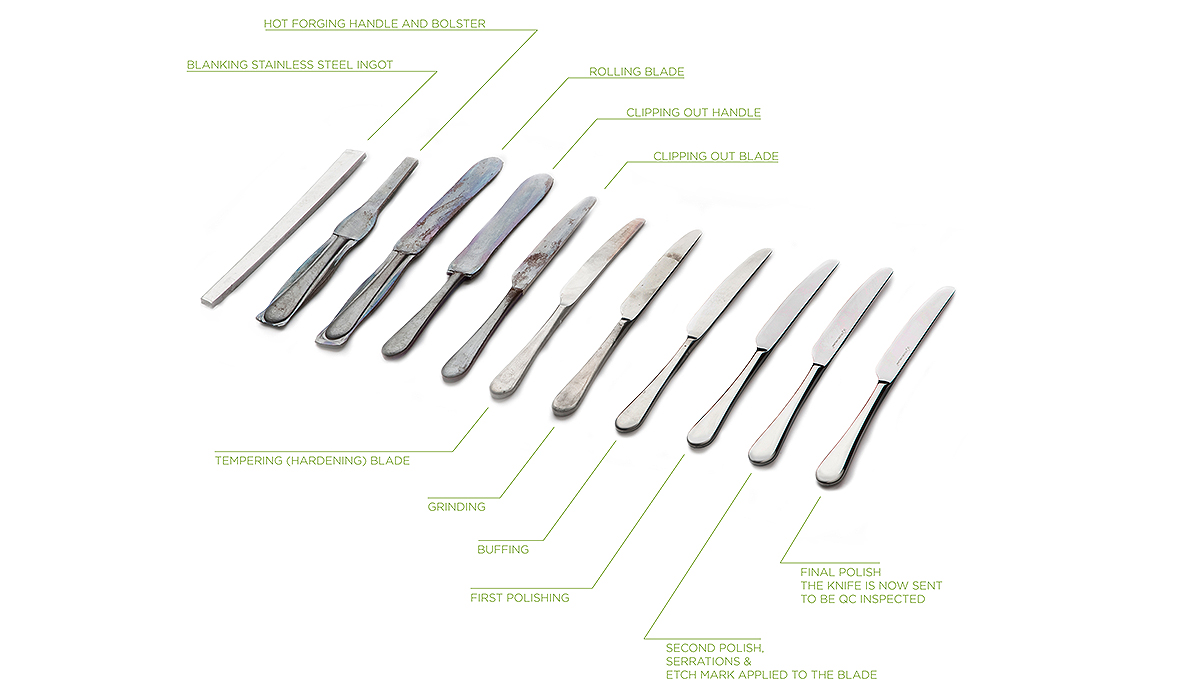

Some of the key moments in creating a knife

Our knives are hot forged in 13 Chromium stainless steel, they are then hardened to 48-52 HRC, this ensures longevity of the cutting edge and creates resistance to corrosion.

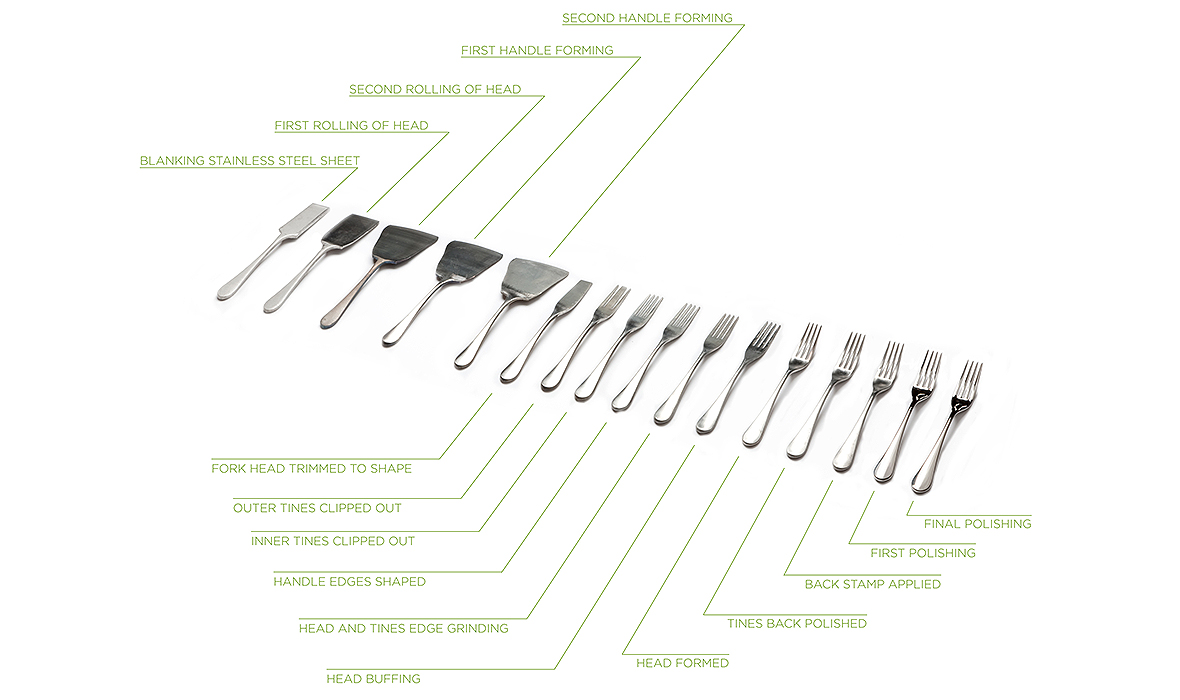

Some of the key moments in creating a fork

Our forks are made by cold forging 18/10 stainless steel, due to the thickness of the handles, they are reheated during manufacturing and the handles cold forged again, this allows us to get the soft contours of the design to our desired specifications.

Some of the key moments in creating a spoon

Our spoons are made by cold forging 18/10 stainless steel, due to the thickness of the handles, they are reheated during manufacturing and the handles cold forged again, this allows us to get the soft contours of the design to our desired specifications.

At Studio William our cutlery goes through approximately 45 processes and finishing techniques for every single piece.

We really care about the smallest detail to make sure our cutlery designs stand the test of time. Not only do we use the highest quality of material available for all our products, but every piece is also inspected by our Quality Control Team before packing just for you. This ensures that you always attain a finish of perfection.